Examine This Report about Overland Conveyors

Table of ContentsThe Ultimate Guide To Overland ConveyorsThe Ultimate Guide To Overland ConveyorsExcitement About Overland ConveyorsOverland Conveyors Fundamentals ExplainedSome Ideas on Overland Conveyors You Need To Know

Air conditioning motors are usually utilized to power the wheel that moves the belt. Phase Five Conveyor System Applications As automation as well as production have ended up being much more highly progressed, conveyors have quickly turned into an important part of material processing as well as activity as well as improving the speed of various production procedures.Conveyors transportation the piece right into the heat heating systems for the sintering procedure. Product packaging: A packaging conveyor is made to aid with product packaging, such as positioning ended up items in containers, effective labeling, or preparation of products for shipping. The feature of a product packaging conveyor system is to relocate items from conclusion and assembly for delivery.

Extract conveyors are used to eliminate molded items from the pressing line or on various other procedures. Airport terminal: Though airports have people relocating conveyors, the main conveying system is for travel luggage handling, which quickens the procedure of obtaining luggage from the checkin counter to the plane and off the plane to baggage pickup.

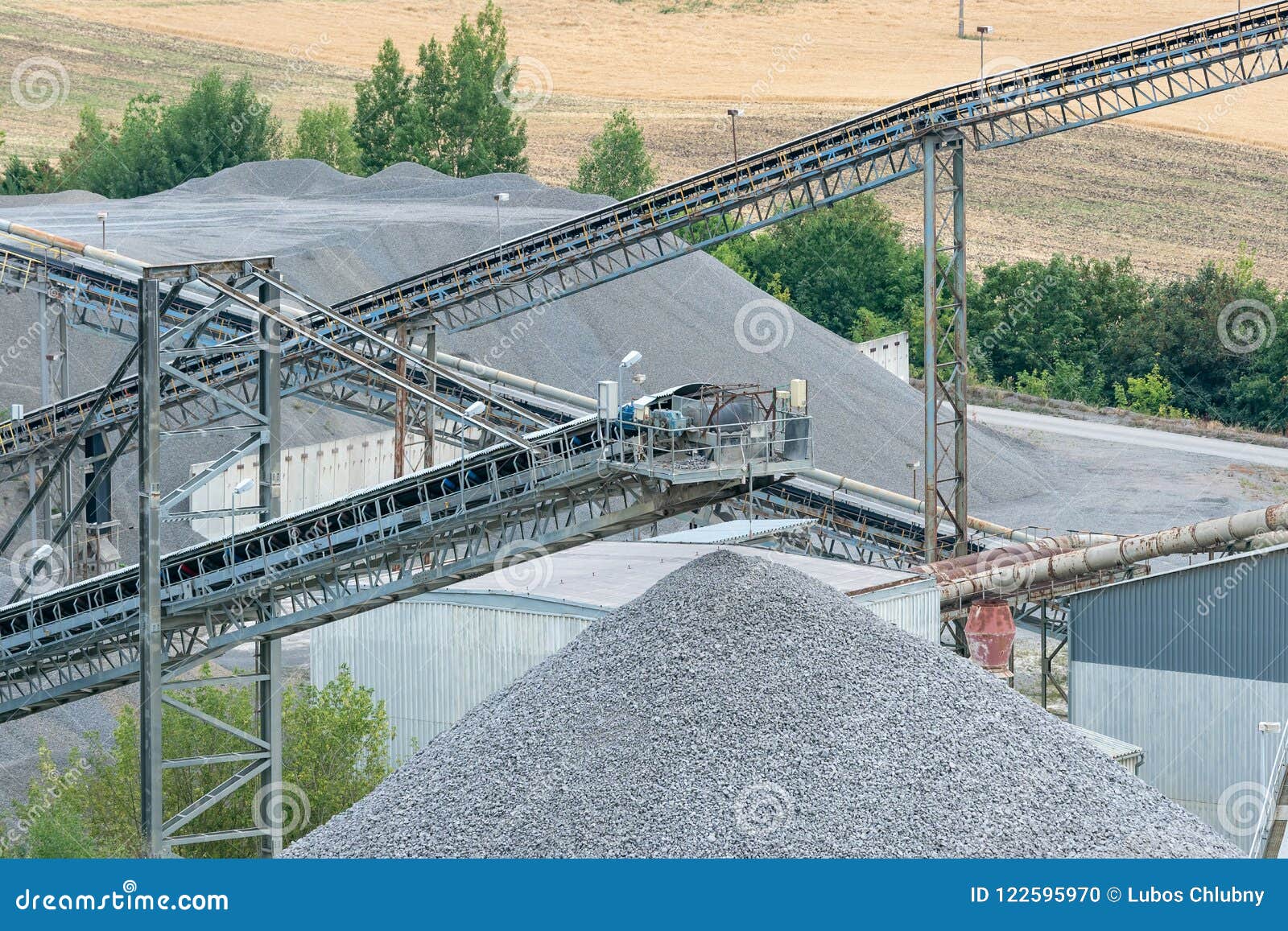

Though mining conveyors vary in dimension and length, the bulk of them get on a slope as well as move several heaps of material. They need to be uniformly loaded to stay clear of splilling or voids. Relying on the style, they operate very quickly approximately 100 fpm. Mining Conveyor Automotive: The auto market makes use of a number of varieties of conveyors for product handling.

Fascination About Overland Conveyors

The one factor that makes them special is the requirement to fulfill governmental policies for hygiene and cleanliness. Printing: Printing conveyors, for display printing, make use of a conveyor dryer procedure for drying display published material. Though there are other techniques for drying out display prints, conveyor clothes dryers are used for huge volume production and be available in numerous varieties.

Phase Six Benefits of a Conveying System Conveyors have actually become a fundamental part of production, mining, production, and also completing procedures. They raise effectiveness and also help in reducing labor prices. Using conveyors has actually resulted in better quantity, increased manufacturing, and avoidance of injuries. Despite the market, conveyors have been verified to be an increase for manufacturing procedures.

Continuous Procedure: Products are constantly loaded and also unloaded for lengthy periods of time without disturbance or deduction. Automated Unloading: Conveyors can be created to automatically unload products without the requirement for hands-on labor. Control of Activity: Communicating systems have rate controls to monitor just how quickly products move along the system, which removes the concern for taking care of issues or damage.

The demand for upkeep depends on the conveyor's use as well as atmosphere. Safety and security: Conveyors are the safest technique for relocating materials via a center or production flooring.

Overland Conveyors - The Facts

The picture listed below is of a safety cable stop for conveyors. High Quantity: Conveyors belong of an automatic system efficient in moving hundreds or countless lots of product per hour or in a day. Chapter Seven Conveying System Malfunctions There are breakdowns that can take place in a sharing system that is continually being used.

Slippage Slippage on a belt conveyor can occur as a result of tension being expensive or low, which can bring about stretching and conveyor belt slippage. Obstruction Conveyor systems are designed to operate continually without disruption or deduction. Any type of kind of obstruction can be damaging to the system and bring about significant repair services. Overland Conveyors.

The most usual is when material sticks to the belt as well as goes past the transfer point Get More Information and also falls off. Splilling When a belt conveyor is overwhelmed, or too stuffed, materials can fall off the sides.

Overland Conveyors Things To Know Before You Buy

On some celebrations, the strengthened material stays and also causes the screw to work harder, which puts pressure on the centerline of the screw. Conveyor System Maintenance Though it might seem that a sharing system is one device, in reality, it is a system of several connecting items that depend on each other to function properly.

Repair Service or Change Making the choice to replace an element on a system has numerous price elements, such as the downtime for the system, discovering the appropriate component, and also working with a professional to do the substitute. This expenditure can be countered with routine upkeep as well as surveillance of the system. Electric motor The vital component of a conveying system is its motor.

Bearing failure can be attributed to lubrication troubles. This can be stayed clear of by having a routine maintenance cycle for bearing upkeep. The temperature degree of the electric motor need to never ever surpass its advised operating temperature level. Wheel Bearings Wheel bearings are entirely loaded with lube to stay out water as well as pollutants. They never ever require repair work if they are consistently examined and also preserved.

Overland Conveyors - The Facts

Cleansing Regardless of the sort of system, keeping it tidy is essential. Belts, rollers, chains, motors, slats, and also all visible areas should official website be cleaned consistently. This is specifically real with items that have actually obtained some form of treatment or finishing, which can trigger parts to end up being polluted and also be seriously damaged.